|

New Mexico, in southeast Albuquerque |

|||

|

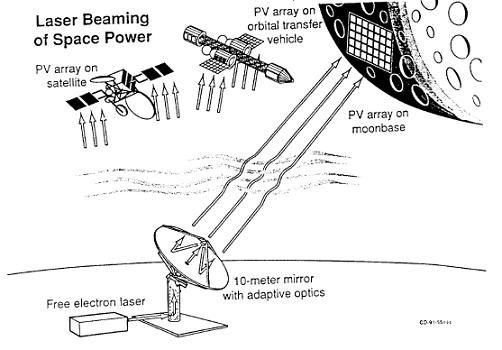

Laser Power Transmitters or Solar Collectors? +34° 57' 54.47", -106° 30' 44.09" ..

..

..

|

|||

|

....

|

|||

Related Links:

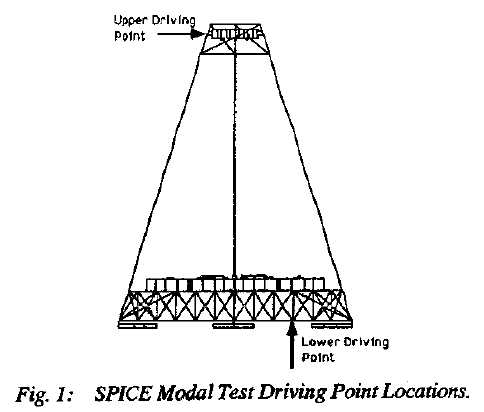

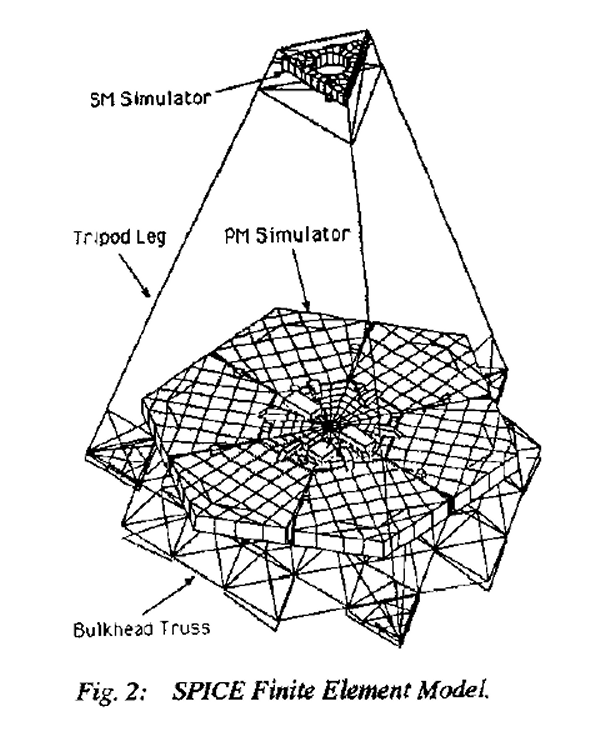

Since it is not obvious how such a system would respond to such disturbances, it is prudent to produce a model to simulate such a system, so that one may have confidence that the system will work if it gets to the hardware stage. |

|||

|

....

Related Links:

|

|||

|

at National Solar Thermal Test Facility ..

New SunCatcher power system unveiled

at National Solar Thermal Test Facility

Stirling Energy Systems (SES) and Tessera Solar unveiled last week four newly designed solar power collection dishes at Sandia’s National Solar Thermal Test Facility (NSTTF). Called SunCatchers™, the new dishes have a refined design that will be used in commercial-scale deployments of the units beginning in 2010. “The four new dishes are the next-generation model of the original SunCatcher system. Six first-generation SunCatchers built over the past several years at the NSTTF have been producing up to 150KW [kilowatts] of grid-ready electrical power during the day,” says Chuck Andraka (7337), the lead Sandia project engineer. “Every part of the new system has been upgraded to allow for a high rate of production and cost reduction.” Chuck and Sandia’s concentrating solar-thermal power (CSP) team have been working closely with SES over the past five years to improve the system design and operation. The modular CSP SunCatcher uses precision mirrors attached to a parabolic dish to focus the sun’s rays onto a receiver, which transmits the heat to a stirling engine. The engine is a sealed system filled with hydrogen. As the gas heats and cools, its pressure rises and falls. The change in pressure drives the piston inside the engine, producing mechanical power, which in turn drives a generator and makes electricity. The new SunCatcher is about 5,000 pounds lighter than the original, is round instead of rectangular to allow for more efficient use of steel, has improved optics, and consists of 60 percent fewer engine parts. The revised design also has fewer mirrors — 40 instead of 80. The reflective mirrors are formed into a parabolic shape using stamped sheet metal similar to the hood of a car. The mirrors are made by using automobile manufacturing techniques. The improvements will result in high-volume production, cost reductions, and easier maintenance. “The new design of the SunCatcher represents more than a decade of innovative engineering and validation testing, making it ready for commercialization,” says Steve Cowman, Stirling Energy Systems CEO. “By utilizing the automotive supply chain to manufacture the SunCatcher, we’re leveraging the talents of an industry that has refined high-volume production through an assembly line process. More than 90 percent of the SunCatcher components will be manufactured in North America.” In addition to improved manufacturability and easy maintenance, the new SunCatcher minimizes both cost and land use and has numerous environmental advantages, Chuck says. “They have the lowest water use of any thermal electric generating technology, require minimal grading and trenching, require no excavation for foundations, and will not produce greenhouse gas emissions while converting sunlight into electricity,” he says. Tessera Solar, the developer and operator of large-scale solar projects using the SunCatcher technology and sister company of SES, is building a 60-unit plant generating 1.5 MW (megawatts) by the end of the year either in Arizona or California. One megawatt powers about 800 homes. The proprietary solar dish technology will then be deployed to develop two of the world’s largest solar generating plants in Southern California with San Diego Gas & Electric in the Imperial Valley and Southern California Edison in the Mojave Desert, in addition to the recently announced project with CPS Energy in West Texas. The projects are expected to produce 1,000 MW by the end of 2012. Last year one of the original SunCatchers set a new solar-to-grid system conversion efficiency record by achieving a 31.25 percent net efficiency rate, toppling the old 1984 record of 29.4.-- Chris Burroughs SOURCE: Sandi Labs, Kirtland AFB |

|||

| FAIR USE NOTICE: This page contains copyrighted material the use of which has not been specifically authorized by the copyright owner. Pegasus Research Consortium distributes this material without profit to those who have expressed a prior interest in receiving the included information for research and educational purposes. We believe this constitutes a fair use of any such copyrighted material as provided for in 17 U.S.C § 107. If you wish to use copyrighted material from this site for purposes of your own that go beyond fair use, you must obtain permission from the copyright owner. | |||

|

|